wye delta starter troubleshooting

This class is NOT VALID for Journeyman Broward License State License or Contractor License. Thread starter Similar threads Forum Replies Date.

Star Delta Motor Starter Troubleshooting

Unlike all other types of starters the VFD can use frequency to limit the power and current delivered to the motor.

. The star delta starting is an inexpensive two-step method of induction motor startingThe motor designed for delta running is started across full line voltage by connecting the phases in star as shown in diagram. Rockwell Automation provides soft starters capable of direct wiring up to wye-delta motors. Up to 24 cash back Wye-delta Transformation is already discussed in our lesson four blog but here we will give some examples and we will explain slowly step-by-step.

Check the Wye-Delta connections for arching or burn marks. Make sure the connections are tight. Any application where the motor is heavily loaded from the start will not work with a star delta starter.

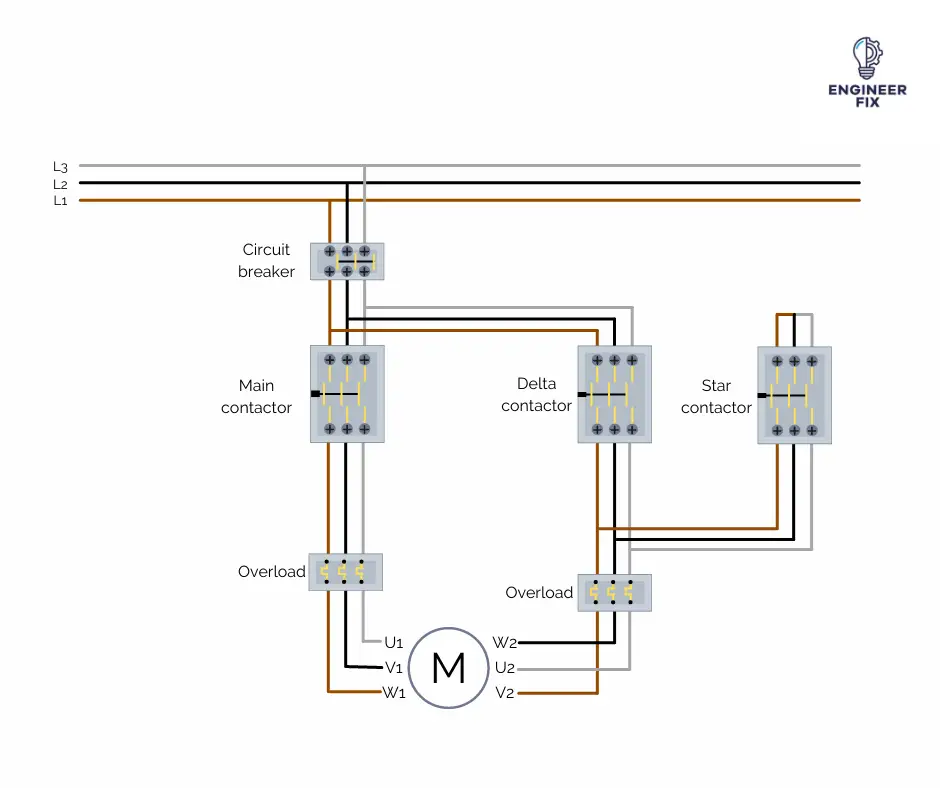

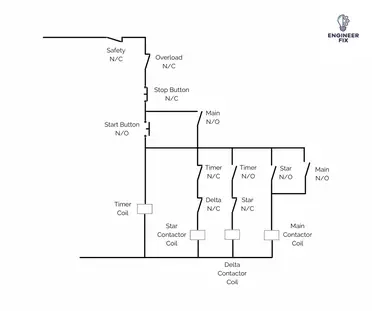

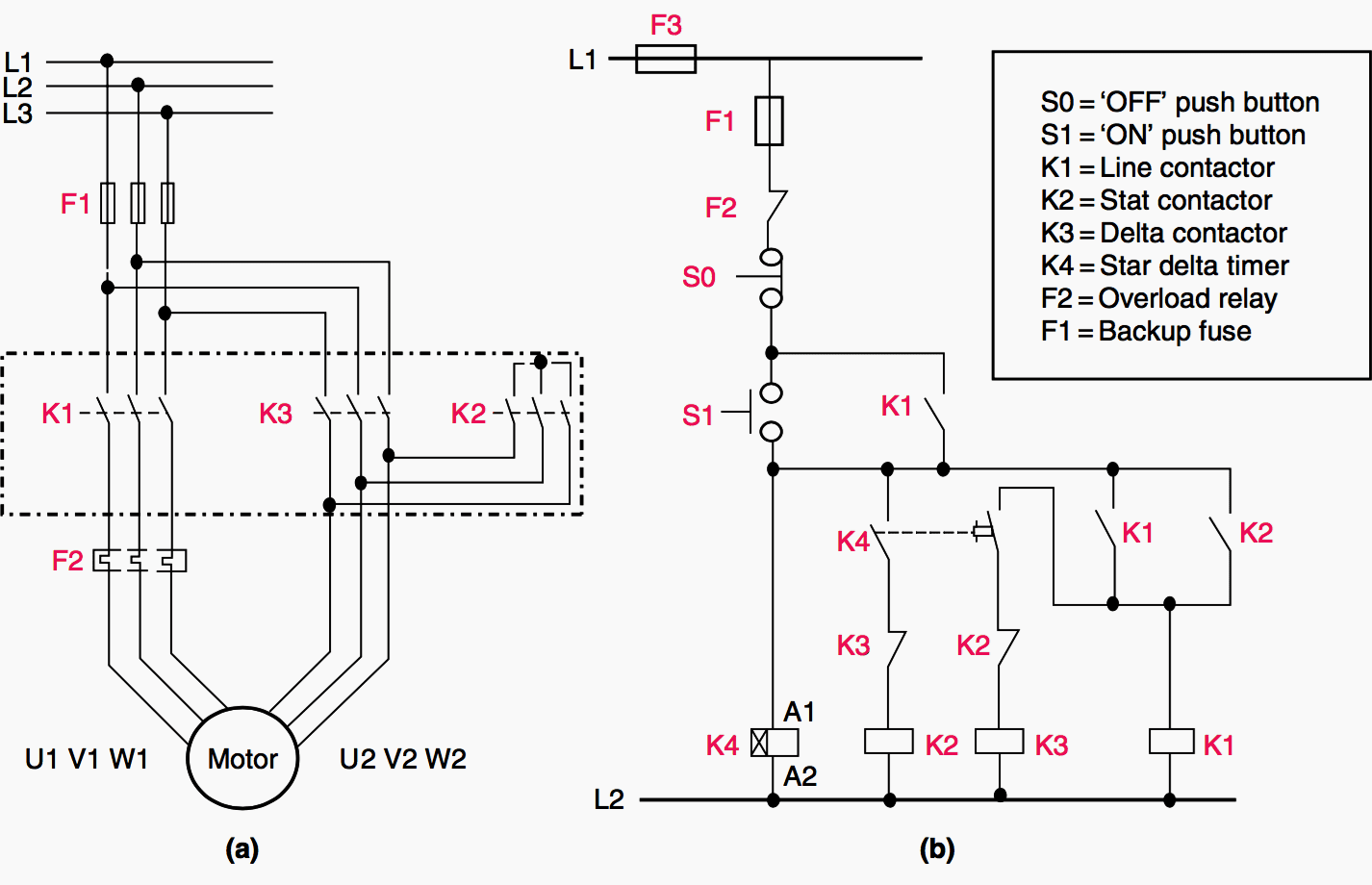

The typical circuit includes three separate contactors an overload relay a timer and an interlock. It is the so-called open transition wye-delta starter thats the culprit. An advantage of the Wye connection is that it can provide multiple voltages without the need for additional transformers.

Wye delta starter troubleshooting. There is an open coil on one of the Wye-Delta contactors. Find Rab and i.

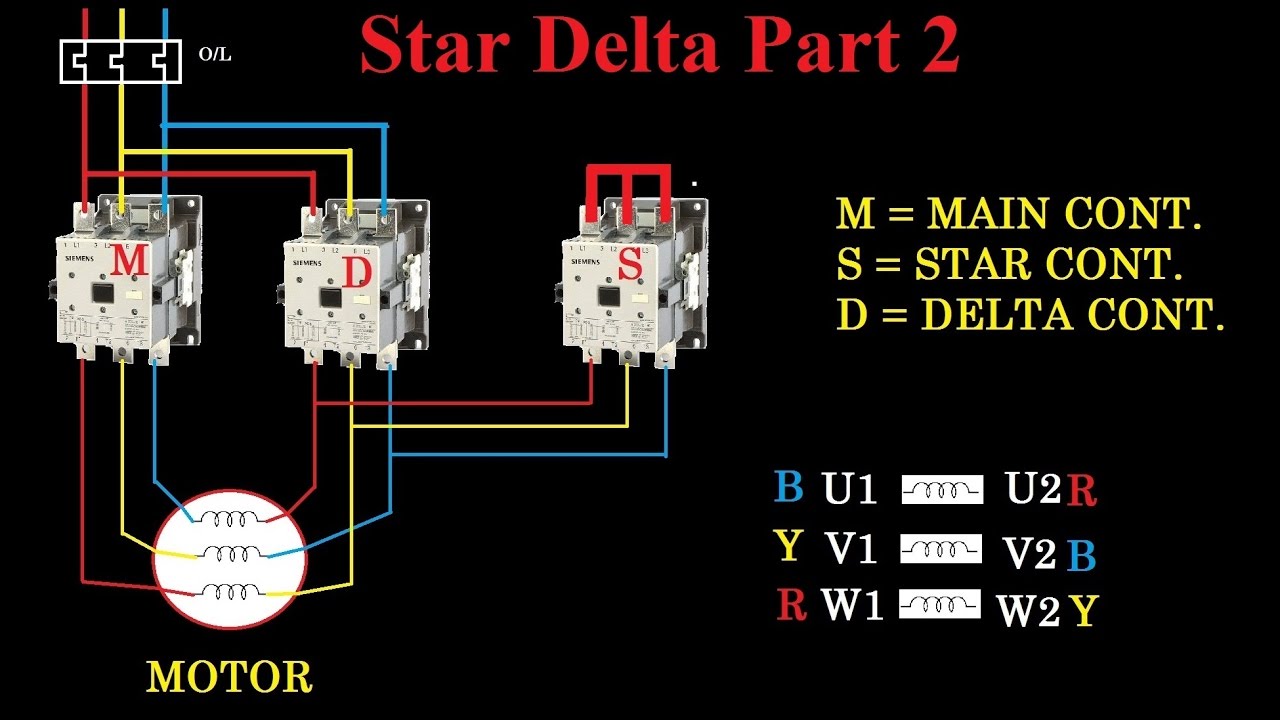

After a period of time adjusted by - timer current sensor etc or when the motor reaches approximately 80 full speed contactor 2M 2S are energized connecting the motor in a delta configuration. This is because the amount of torque present is only about 30 of a direct online starter. Starting the Wye Delta.

Star-delta starter Wye-Delta Starters Circuit working. Star-delta starters are cheaper than soft-starters and are widely seen in small scale. What are the advantages and disadvantages of a Wye-Delta Motor Starter.

Where Isc starting phase current delta Ifl Full load phase current delta sfl slip at full load. In addition the form factor is typically much smaller with a soft starter than that of an electro-mechanical. The counter emf should have been reduced.

Make sure the connections are tight. Determine the unknown resistance R3 in the circuit of Figure 80. Start delta starters are normally only used on low to medium torque start applications.

Induction motors are robust and reliable and are used in all industries across the globe. This would require another timer. Once the motor runs at full speed in wye disconnect the power to the wye contactor coil let the speed fall to half and then connect power to the coil of the delta contactor.

There are numerous papers written about this available on the. Check out a sample QA here. What are the advantages and disadvantages of a Wye-Delta Motor Starter.

This course describes the similarities and differences between a wye-delta motor starter application and a full-voltage motor starter application. Check the Wye-Delta connections for arching or burn marks. Some wye-delta starters for large motors can cause peak currents in the power system to exceed the normal trip settings of branch circuit breakers.

Closed transition starters do not permit this peak to occur. The star-delta wye-delta starting method controls whether the lead connections from the motor are configured in a star or delta electrical connection. When the start command is issued contactor 1M is closed connecting the motor in a Wye configuration.

Applications with a load torque higher than 50 of the motor rated torque will not be able to start using the start-delta starter. Wye start delta run motor wiring diagram What is a Wiring Diagram. There is an open coil on one of the Wye-Delta contactors.

A wiring diagram is a straightforward visual representation from the physical connections and physical layout associated with an electrical system or circuit. Various methods are followed to start induction motors out of which star-delta starters are the most commonly used ones to reduce the starting current. Analog Mixed-Signal Design.

View Wye-Delta and Solid State Starter Application Guide for more information and detail on wye-delta starting. This is a very well known problem with Open Transition Wye-Delta starting. 1-bit to PCM conversion in Delta-Sigma converters.

This class apply to Local Union 725 Collective Bargaining Agreement CBA. Both types are diagrammed in accompanying illustrations. The initial connection should be in the star pattern that results in a.

There is a loose connection on the WYEDELTA buss connectors. A sample wiring diagram is included as Figure 9 on page 14. Want to see the full answer.

Published September 19 2016. Delta to wye conversion of sources. You switch from wye to delta after 25 to 4 seconds but the switch is instantaneous.

Inspect the WYEDELTA contactor buss connections make sure they are making all the terminal leads. It has to do with the phase shift that takes place when switching from Wye to Delta and how that interacts with any residual magnetism in the motor at that moment and the point in the sine wave at that moment etc. No factory modifications forms are available with the oem.

Delta to Wye Conversion. Spindle load pegs to 200. WYE DELTA MOTOR STARTER DIAGRAM PDF.

In this example there are two Y-networks comprising the first Y-network 24 Ω 30Ω and 30Ω and the second Y-network 10Ω 50Ω and 30 Ω. Solid-State Starters The most widely used configuration of the electromechanical wye-delta starter is referred to as open transition. If one of the windings in a Wye primary fails two of the phases of a Delta secondary will see a reduced voltage.

There is always transition spike when motor from star go to delta connectionthis spike can be a reason for your problem and breaker trippingsometime installation of the timer. The primary and secondary of a three-phase transformer can be. Inspect the WYEDELTA contactor buss connections make sure they are making all the terminal leads.

This video covers the basics of a wye-delta motor starterFor other videos on reduced voltage starting methodsPart-winding starter. The initial connection should be in the star pattern that results in a. William Young Class description.

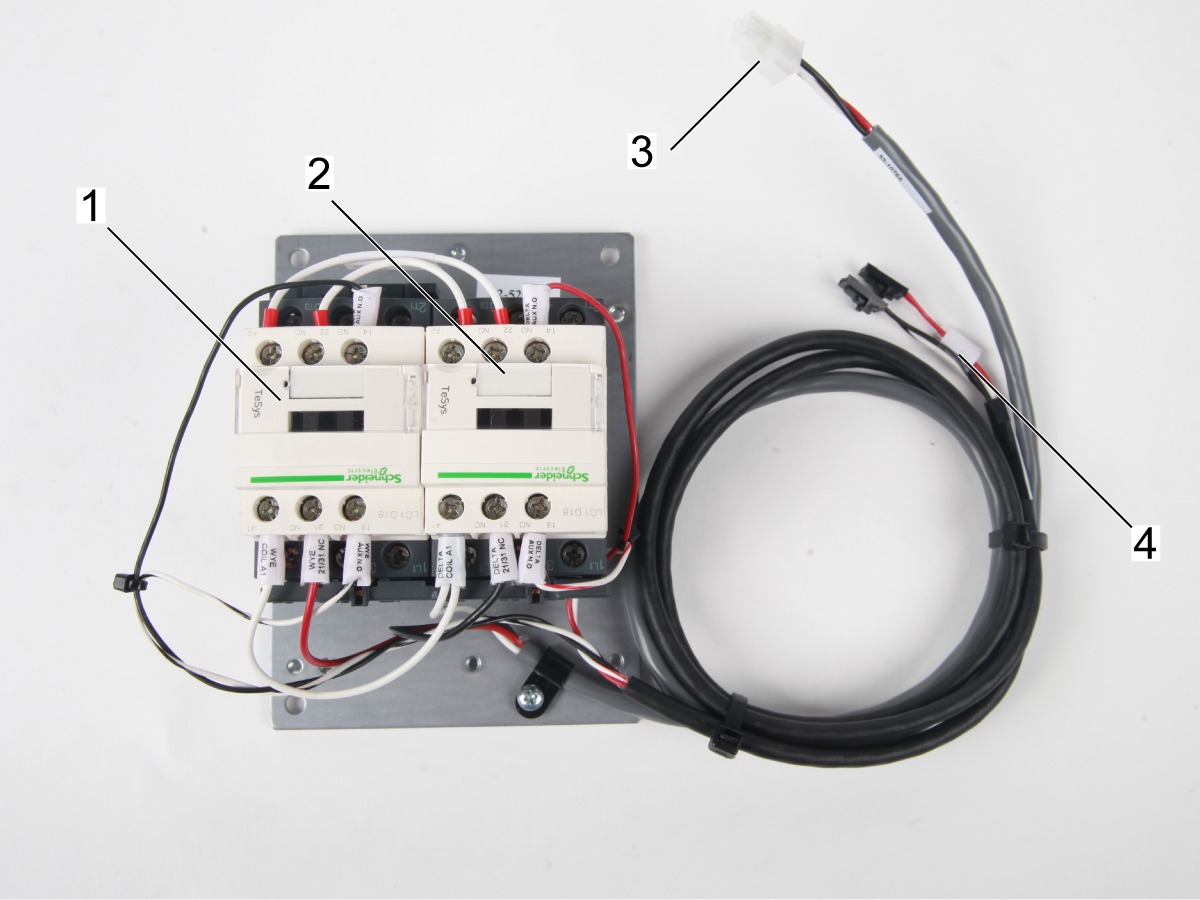

This class covers identifying Components Sequence of operation along with the Maintenance of the Wye Delta Starters. There is a loose connection on the WYEDELTA buss connectors. Spindle load pegs to 200.

If the secondary is also Wye connected two phases will have reduced voltage and the other will have zero volts.

Wye Delta Contactor Troubleshooting Guide Chc

Automatic Star Delta Starter Control Circuit Diagram With Timer

How To Troubleshoot 3 Phase Induction Motor Step By Step Guide Engineer S Portal

Power Circuit Of Wye Y Delta D Starter Electrical And Electronics Technology Degree

How To Test Star Delta Starter Star Delta Starter Troubleshooting Troubleshooting Motor Starter Youtube

Star Delta Starter Circuit Y D How To Wire Pros And Cons

Star Delta Starter Circuit Y D How To Wire Pros And Cons

Star Delta Starter Complete Wiring For 3 Phase Motor Star Delta Control Connection Explained Youtube

Star Delta Starter Part 2 Youtube

Star Delta Motor Starter Troubleshooting Youtube

How To Troubleshoot 3 Phase Induction Motor Step By Step Guide Engineer S Portal

3 Phase Induction Motor Star Delta Connection

Star Delta Starter Plc Program And Wiring Part 5

45 Best Of Wye Delta Starter Wiring Diagram Circuit Diagram Electrical Wiring Diagram Electrical Circuit Diagram

Motor Problem In Star Delta Starter In Air Compressor Electrical Engineering Stack Exchange

How To Troubleshoot 3 Phase Induction Motor Step By Step Guide Engineer S Portal

Star Delta Starter Theory And Working With Power And Control Circuit Electrical Technology All About Electrical Engineering

Star Delta Starter Explained Working Principle Youtube

Troubleshooting Three Basic Hardwired Control Circuits Used In Starting Electric Motor Eep